Typically, cruisers are most concerned with where their cruise ship is going. However, some cruise fans are inquisitive enough to wonder not only where their ship came from but how it was built.

If you’ve ever been curious about how these massive feats of engineering are constructed — and by whom — this article will demystify all the nuts and bolts of where cruise ships are built.

Call to Book Your Next Cruise Now: 1-855-228-5584!

Where are Cruise Ships Built?

Shipyards are scattered across the globe, but there are a handful that specialize in passenger ships. These heavyweights of cruise ship construction are primarily clustered in Europe.

The following are the world’s most prominent shipyards specializing in cruise ship construction, along with which of your favorite floating resorts they have built.

Fincantieri (Monfalcone, Italy)

For over 30 years, Italian shipyard Fincantieri has constructed more than 100 cruise ships across 18 brands. This includes:

- 19 Princess Cruises ships (including Crown Princess in 1990)

- 17 Holland America Line ships

- 15 Carnival Cruise Line ships

- 14 Costa ships

- 11 Ponant ships

- 10 Viking Ocean ships

- Four Silversea ships

- Four P&O Cruises ships

- MSC Cruises’ Seaside Class, including MSC Seascape

- Three Hapag-Lloyd cruise ships

- Cunard’s Queen Victoria and Queen Elizabeth

- Disney Magic and Disney Wonder

- Oceania Riviera and Oceania Marina

- Seabourn Encore and Seabourn Ovation

- Regent’s Seven Seas Explorer and Seven Seas Splendor

- Virgin Voyages’ Scarlet Lady, Valiant Lady, and Resilient Lady

- Hurtigruten’s Fram

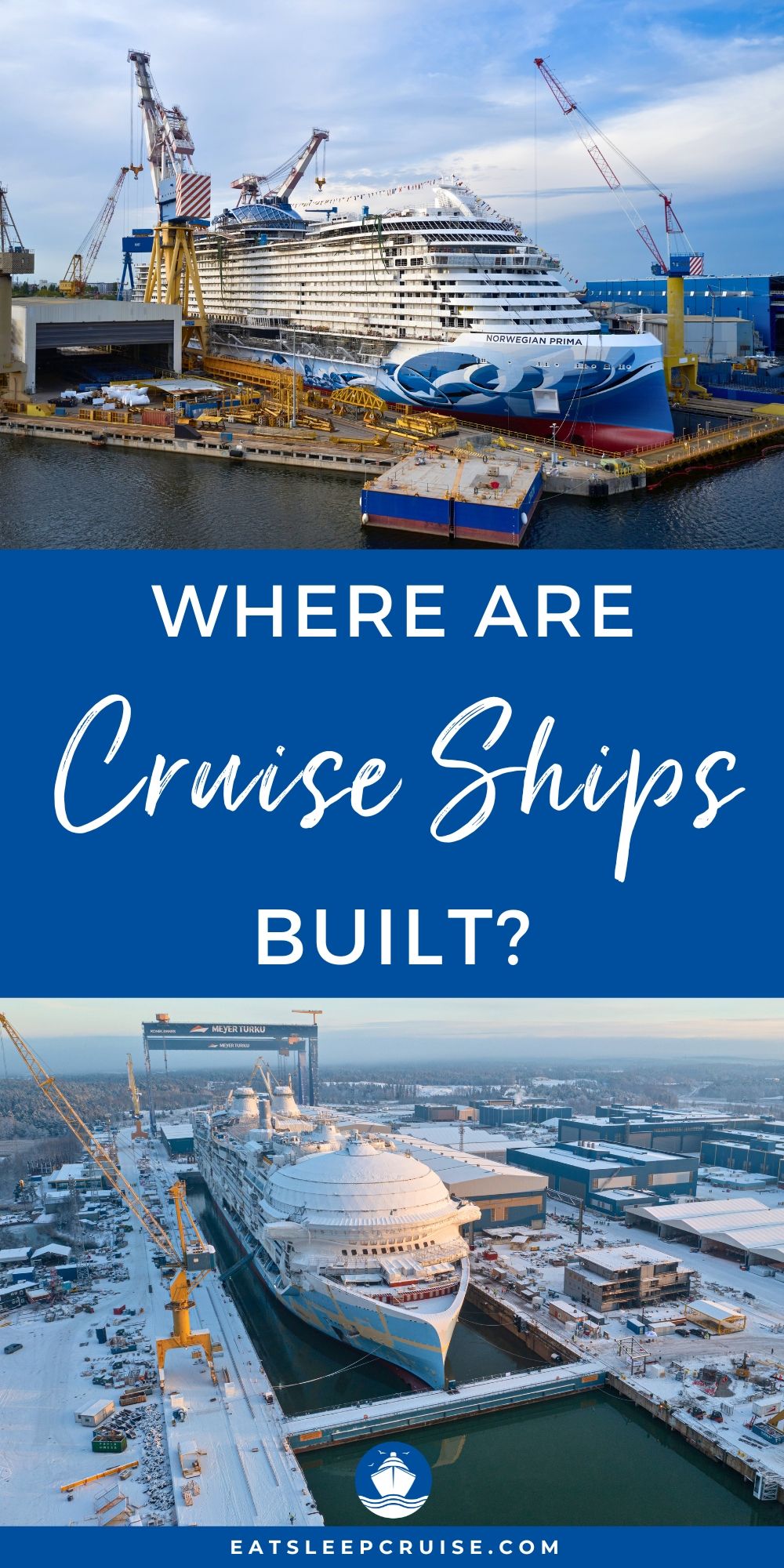

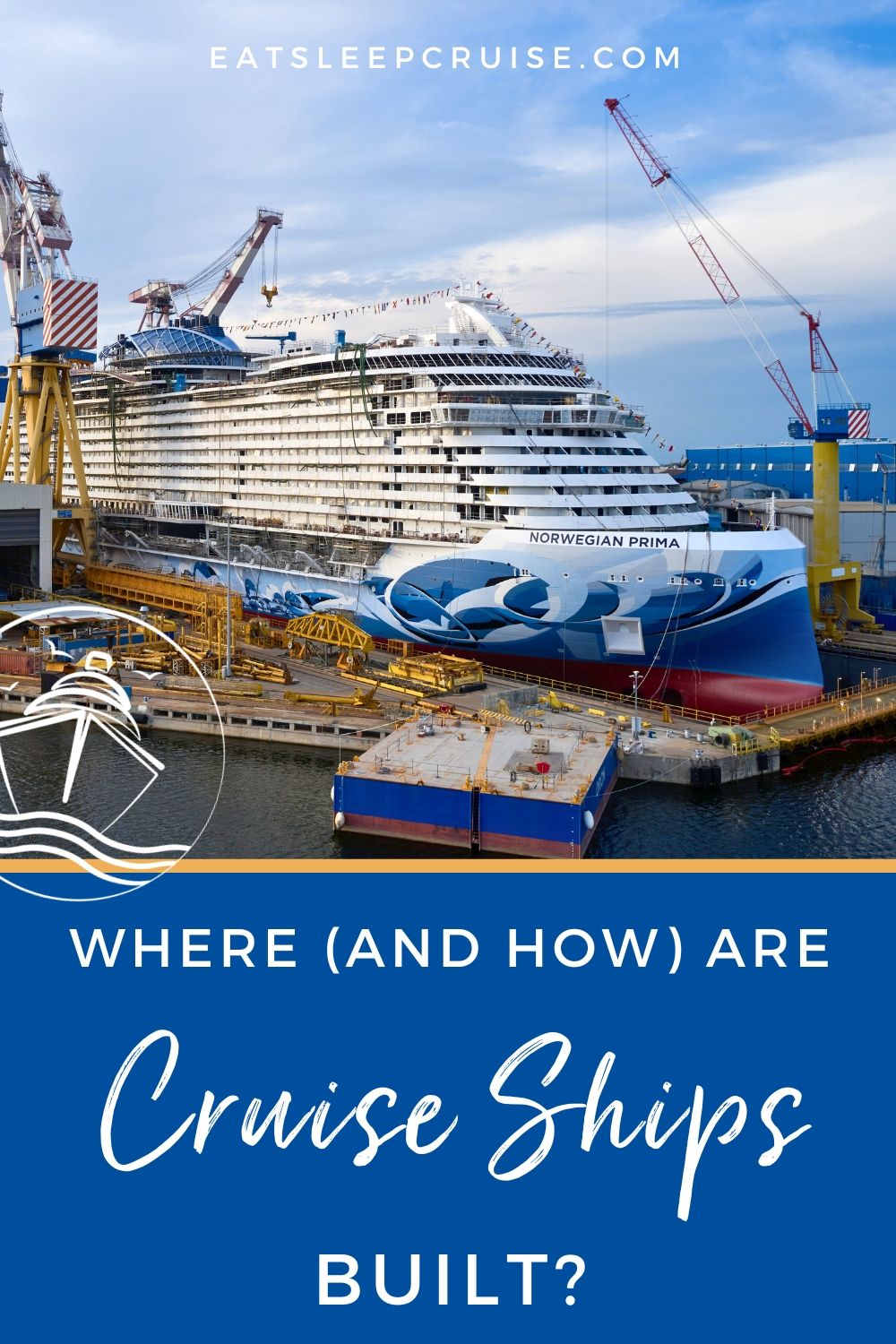

- Norwegian Prima and Viva

Chantiers de ‘lAtlantique (Saint-Nazaire, France)

Formerly STX Europe, the Chantiers de l’Atlantique shipyard in France is responsible for more than a century of shipbuilding, beginning with the SS France in 1912. Today, its portfolio includes:

- Holland America’s Nieuw Amsterdam and Noordam, in 1983 and 1984, respectively

- 15 MSC Cruises ships

- 11 ships for Royal Caribbean International, with Utopia of the Seas currently under construction

- While Renaissance Cruises is no longer operating, the eight R-Class ships built here remain in service

- Seven Celebrity Cruises vessels, including Celebrity Beyond and Celebrity Apex

- Norwegian Windward, Norwegian Dreamward, and Norwegian Epic

- Coral Princess and Island Princess

- Hapag-Lloyd’s Europa 2

- Crystal Serenity (2003)

- Cunard’s Queen Mary 2 ocean liner

Meyer Group (Germany and Finland)

The Meyer family of Meyer Group shipyards have been in shipbuilding for an astounding seven generations and 225 years. There are three Meyer locations: Neptune Werft in Rostock, Germany; Meyer Turku in Turku, Finland; and Meyer Werft in Papenburg, Germany, which is the largest.

Modern cruise ship building began for Meyer in the 1970s, with Royal Viking Line. Their ship, Royal Viking Star, has since been rechristened three times and operates today as Black Watch under British cruise line Fred. Olsen. To date, Viking Cruises has had more than 60 Viking river ships built at Neptune Werft.

The following are some more significant builds from these three related shipyards:

- Royal Princess (1984) in Turku

- Crown Odyssey (now Balmoral) at Meyer Werft in 1988

- 22 Royal Caribbean ships, including Oasis and Icon of the Seas

- Carnival Cruise Line’s Fantasy Class (eight ships), plus the newer Excel-class ships (Mardi Gras, Carnival Celebration, and Carnival Jubilee)

- 11 Norwegian Cruise Line ships, including Pride of America and Norwegian Encore

- 10 AIDA (German) ships

- Five ships for Celebrity Cruises

- Disney Wish and Disney Treasure

- Crystal Symphony (1995)

- Silversea’s Silver Nova (2023) and Silver Ray (2024)

EXCLUSIVE SAVINGS: Get Deals When Booking Your Next Cruise!

How Are Cruise Ships Built?

When a cruise line decides to build a new cruise ship, they must award the contract to a shipyard. Some brands frequently use the same shipyard for all new-builds, while others might shop around depending on their needs (and the availability of the shipyard). Many times, cruise companies will stick with the same shipyard for an entire class of ships, given that construction should be similar.

While the finer details will differ from ship to ship, the overall process of constructing a massive vessel like this is similar, regardless of the shipyard. Cruise ships are pieced together like a puzzle, with various components built in blocks and then fitted together. A watertight hull is the main building block upon which all other pieces rely.

It could take months between the planning and design phase to “cutting the steel”. This is considered the first milestone in cruise ship building. Once construction is underway in earnest, large cranes are used for some serious heavy lifting to move more than a thousand tons of cruise ship building blocks into place.

Most of these blocks, from staterooms and panels to furniture and bathroom fixtures, are built offsite before moving to be put in place at the shipyard. Cabins are actually constructed individually and then slid into the greater structure.

The shipbuilding process takes a year to 18 months on average to construct a modern cruise ship. According to major shipyard Fincantieri, it takes 135,000 hours of planning; and 2 million hours of work to build the average cruise ship.

Prior to its first cruise, a new ship undergoes a series of tests to determine if it is seaworthy. These are referred to as “sea trials” and include tests of safety systems, speed and propulsion, navigational systems, maneuverability as well as noise and vibrations onboard.

What Are Cruise Ships Made of?

While cruise ship interiors vary widely in fabric choices, furnishings, and paint colors, the skeleton of any vessel is similarly constructed.

The exterior of a cruise ship is created using steel and aluminum alloys. Weight must always be kept in mind and properly balanced to keep the ship from being too top heavy or uneven. For that reason, lightweight carbon fiber is often employed to help offset the weight of the steel structure.

Of course, building a floating hotel is not the same as constructing a hotel or resort on land. Special considerations must be made regarding fire safety, so combustible materials like wood are never used. Every cruise ship has fire zones outfitted with fire doors, in case of emergency. Fire-resistant materials are also utilized throughout the vessel to reduce the chance of a widespread hazard.

In terms of sound and vibration, cruise ships are essentially insulated with shock-absorbing structures and materials to reduce rattling and prevent excessive movement while your ship rides the waves.

How Often Are Cruise Ships Refurbished?

Cruise ships are regularly refurbished to keep them looking fresh as well as in good working order. Most ships go into what is called “dry dock” every few years for a variety of upgrades.

Refurbishments can be as simple as routine maintenance to touch up paint, replace carpeting, upholstery or soft furnishings, which might last a few days’ time. But refurbs can also include major overhauls of ship spaces lasting weeks or months. If a new feature (like a restaurant) is being rolled out across a fleet, it will be applied to older or existing vessels in the form of a dry dock.

When ships are due for a refurbishment, they don’t go back to their original shipyard. Instead, they head to a dockyard that specializes in this type of cruise ship work. These dockyards are also spread far and wide, from Brest, France and Cadiz, Spain to Freeport, Bahamas and even within the U.S., from Portland, Oregon to San Diego.

BOOK NOW: Exclusive Rates on Your Next Cruise!

Comments

Do you find it interesting as to where and how cruise ships are built? Did you know all the intricacies of shipbuilding and refurbishments? Drop us an anchor below to share your thoughts.